Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

A Practical Study on Concrete by Partial Restitute of Cement by Orange Peel Ash in Additive with Polypropylene Fibers on M40 Mark

Authors: M. Jahera Bee, P. Subhasri

DOI Link: https://doi.org/10.22214/ijraset.2024.63647

Certificate: View Certificate

Abstract

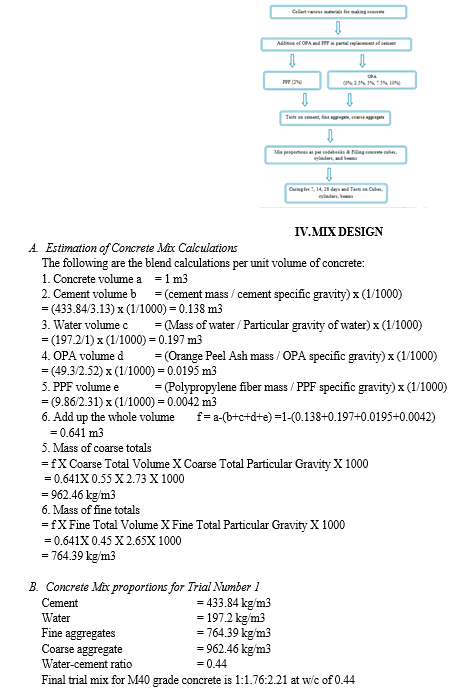

Researchers have been looking at several materials to make concrete more sustainable in the past few years. The nutritional and therapeutic benefits of orange fruits have kept them in human diets for centuries. However, improper disposal of the orange peel wastes produced by fruit eating poses risks to both human and environmental health. The study\'s overarching goal was to develop environmentally friendly engineering material additions for use in concrete, with a secondary objective of reducing trash pollution and littering. With a focus on the strength properties of OPA-cement blends for cement replacement ranging from 0-10% at 2.5% intervals, this investigation will examines the potential of orange peel ash (OPA) as a cement replacement material. The effect of varied % additions of OPA on the qualities of fresh concrete was investigated experimentally by measuring consistency, fineness of cement, soundness of cement, setting times, workability, compressive, split tensile strength and flexural strengths. An ideal concentration of 0%, 2.5%, 5%, 7.5%, and 10% of OPA admixture was determined, and consistency improved with increasing additions on M40 Grade of Concrete. Fiber reinforced concrete is a cementitious composite material with a distributed reinforcement in a form of fibers. Polypropylene fibers (PPF) can be categorized into microfibers and macro fibers depending on their length and the role that they perform in the concrete. An overview of chosen polypropylene fibers (PPF) are used at constant 2% of cement on M40 Grade of Concrete. Moreover, the influence of polypropylene fibers on some properties of concrete such as workability; compressive, flexural, and tensile strength; toughness; water absorption, eco-friendly and economic properties were discussed. In comprehensive of total volume of cement replacement of 0%PPF+0%OPA, 2%PPF+2.5%OPA, 2%PPF+5%OPA, 2%PPF+7.5%OPA and 2%PPF+10%OPA is used on M40 Mark.

Introduction

I. INTRODUCTION

In recent years, researchers have been exploring alternative materials to enhance the sustainability of concrete. One such avenue involves using agricultural waste products as partial replacements for cement. The development of a nation is not solely dependent on its technological insights but also its infrastructure. Thus, concrete has become an indispensable material in the construction industry. The advent of cement/concrete has given rise to making life comfortable and worthwhile through the construction of flyovers, skyscrapers, bridges, dams, and various buildings ranging from hospitals, factories, etc. Cement is one of the most essential components in the production of concrete which gives it, its strong bonding ability and consisting.

A. Background Study

- OPA

Certainly! Let’s delve into the background of Orange Peel Ash (OPA) as a cement replacement material.

Research Findings:

a. Researchers investigated the potential of OPA as a cement substitute, focusing on its impact on various properties of OPA-cement blends.

b. Calcination Conditions: The optimal calcination temperature and time for orange peel were determined. The best conditions were achieved by calcining the peel at 600°C for 2 hours.

2. PPF

Certainly! Let’s explore the background of polypropylene fibers:

a. Polypropylene (PP) is a t0hermoplastic polymer. It was developed accidentally by chemists Robert Banks and J. Paul Hogan in 1951. Later, Italian and German scientists Giulio Natta and Karl Rehn perfected the technique to synthesize polypropylene resin, leading to mass production starting in 1957. The initial trade name for polypropylene was “Moplen,” which remains in use today.

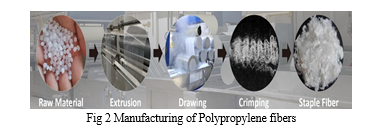

b. Manufacturing Process:

Polypropylene chips are converted into fibers through melt spinning. Spunbonded and melt-blown processes are also essential for nonwovens.

B. Objectives

The objectives of this study are as follows

- To optimize the percentage of partial replacement of PPF&OPA to cement

- To investigate the Strength properties of the cast specimens by both destructive and nondestructive tests

- Usually, the mechanical properties of concrete have been developed namely, compressive, flexural, and tensile strength by adding the fibers.

- In addition, the fiber makes the concrete very durable, tougher and lower permeability four percentages of polypropylene fibers were used while four percentages of high performance cement with orange peel ash were used, in addition to normal specimens of concrete without any admixtures.

C. Scope

- Scope of OPA

Orange peel ash (OPA) has been studied as a potential cement replacement material, and its use can offer several benefits. Let’s explore its scope:

a. Cement Replacement: OPA can partially replace cement in concrete mixtures. Researchers have investigated the effect of OPA content on various properties of OPA-cement blends.

b. Physicomechanical Properties: Studies have focused on properties such as consistency, setting times, soundness, compressive strength, and flexural strength. These properties are crucial for assessing the performance of OPA-blended cement.

c. Calcination Conditions: The optimal calcination temperature and time for orange peel (OP) were found to be 600°C for 2 hours. These conditions ensure the desired chemical composition of OPA.

d. Consistency and Setting Time: As OPA content increases, the water required for consistency also increases due to unburnt carbon content. Additionally, prolonged setting times occur, attributed to reduced clinker content and higher water demand.

e. Strength Considerations: Compressive and flexural strengths decrease with higher OPA content. However, over curing days, strengths improve. Notably, a 5% cement replacement with OPA does not adversely affect strength due to pozzolanic reactions.

2. Scope of PPF

Polypropylene fibers are commonly used in concrete as a reinforcement material, but they do have some limitations. Here are the disadvantages associated with polypropylene fibers in cement:

a. Low Modulus of Elasticity: Polypropylene fibers have a relatively low modulus of elasticity (ranging from 1 to 8 GPa). This means they are less stiff compared to other reinforcement materials like steel.

b. Lower Tensile Strength: The tensile strength of polypropylene fibers is lower (ranging from 140 to 690 MPa) compared to steel. This limitation affects their ability to resist tension forces.

c. Susceptibility to Deterioration: Polypropylene fibers can deteriorate when exposed to sunlight and oxygen. This susceptibility can impact their long-term performance in outdoor applications.

d. Heat Resistance: Polypropylene fibers evaporate at higher temperatures within the concrete pores. Consequently, their heat resistance is relatively low.

II. LITERATURE REVIEW

Haider A. A. Al-Katib, Hayder H. Alkhudery, and Haider Ali Al-Tameemi Faculty of Engineering, University of Kufa, Najaf, Iraq Fiber reinforced concrete is an improved type of concrete that containing fibers randomly distributed inside it. Usually, the mechanical properties of concrete have been developed namely, compressive, flexural, and tensile strength by adding the fibers. In addition, the fiber makes the concrete very durable, tougher and lower permeability. This paper aims to enhance the concrete mechanical properties by adding polypropylene fibers in combination with high performance cement as a partial cement replacement. The combination of both polypropylene fibers and high performance cement in concrete gave excellent values of flexural, tensile and compressive strength. Seven percentages of polypropylene fibers were used while two percentages of high performance cement were used, in addition to normal specimens of concrete without any admixtures. Test results give a well improvement by using both polypropylene fibers and high performance cement. The flexural strength and the tensile strength are increased significantly from 2.7 to 14.5 MPa, and from 1.9 to 7 MPa, respectively. While concrete strength of compression increased from 30.1 MPa to 42.9 MPa due to inclusion of polypropylene fibers and high performance cement. The concrete specimens with including both high performance cement and polypropylene fibers had adequate strength to counteract further cycles of loading after releasing 1st failure load.

III. MATERIALS AND METHODOLOGY

A. Cement

Cement must build up the proper strength. It must signify the proper rheological behavior. Generally equal types of cements have relatively different rheological and strength characteristics, mainly when used in combination with admixtures and supplementary cementing materials. Specific gravity of cement is 3.13. Ordinary Portland cement grade 43 of IS 8112-1976 was used for this project. Portland cement used in this investigation. The tests on the cement were done in Dr kvsr civil labs. I have used the UltraTech cement in this project. The Portland cement conformed to the standards.

B. Fine Aggregate

Sand with particle size less than 4.75 mm, Specific gravity 2.65, Fine aggregate usually consists of natural, crushed, or manufactured sand. Natural sand is the common component for regular weight concrete. In various cases, manufactured light weight particles used for lightweight concrete and mortar. The maximum grain size and size distribution of the fine aggregate depends on the type of product being made.

C. Coarse Aggregate

Use 20 mm crushed stone with a specific gravity of 2.45 & a density of 1389 kg/m3 as coarse aggregate. Smaller sized aggregates make higher concrete strength. Regularly an aggregate with specific gravity more than 2.55 and absorption less than 1.5% (except for light weight aggregates) can be regarded as being of excellent quality. Where aggregates strength is higher, concrete strength is also higher.

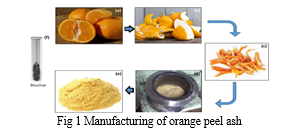

D. Orange Peel Ash

- The ash derived from orange peels (known as OPA) contains a high concentration of CaO and SiO2.

- It’s recommended for rendering, plastering, and as a retarder suitable for hot weather construction.

- For concrete work in very hot and dry conditions prone to rapid dehydration, an OPA content of 20% or more is recommended.

E. Polypropylene fibers

- Polypropylene (PP) is a thermoplastic polymer. It’s manufactured from propylene gas using a catalyst like titanium chloride.

- Unlike other commodity fibers, PP is primarily used for industrial applications rather than apparel or household textiles.

- PP has an intermediate level of crystallinity between low-density polyethylene (LDPE) and high-density polyethylene (HDPE). It also has higher working temperatures and tensile strength than polyethylene.

???????

???????

Conclusion

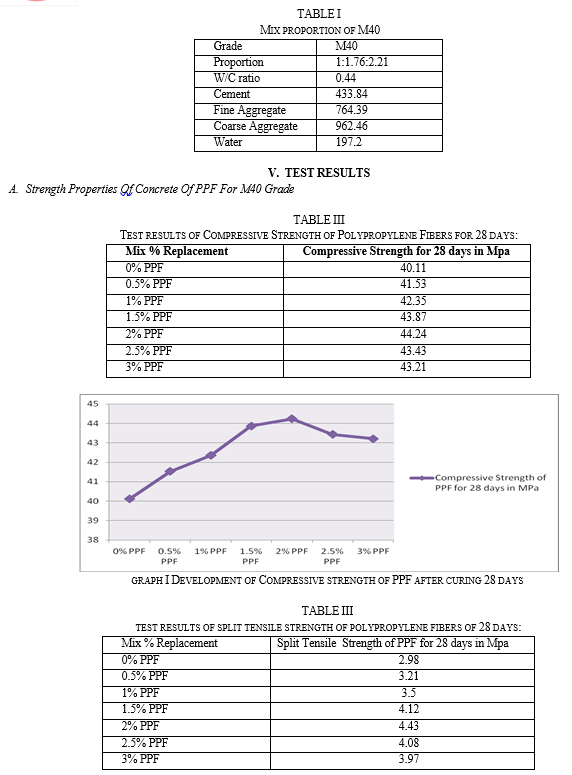

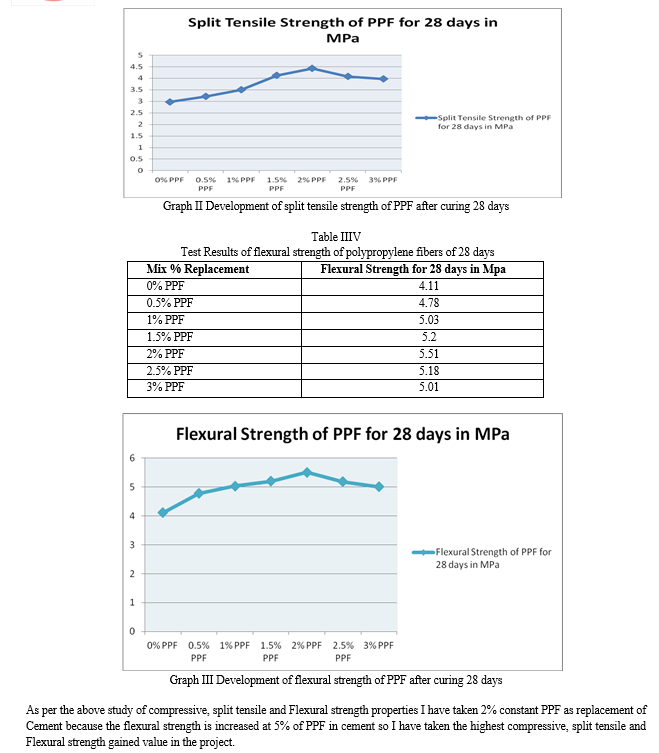

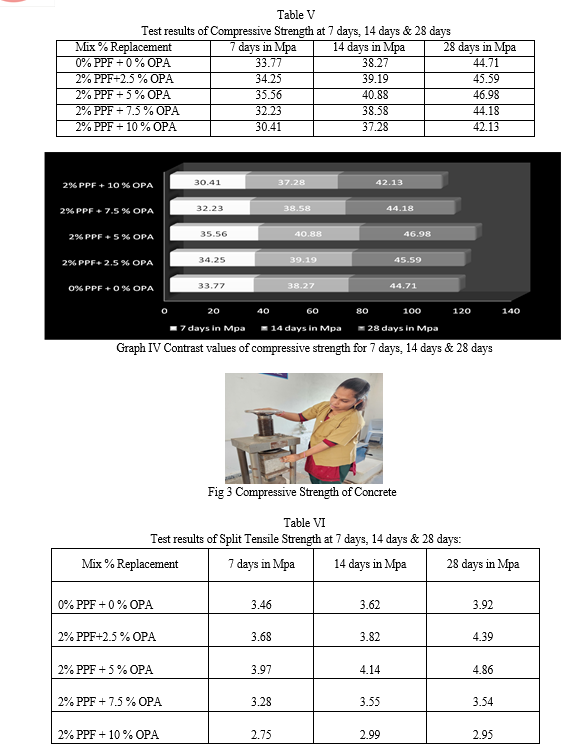

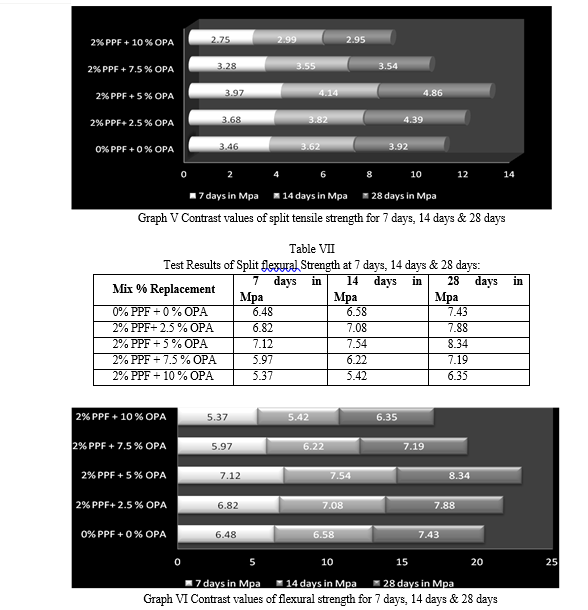

1) The compressive, tensile strength and flexural strength of concrete increased considerably due to using OPA & PPF as cement partial replacement, while the effect of was slightly on the concrete compressive strength. In comparison with the concrete reference mix, the compressive strength increased by 97, respectively due to an optimum 5% replacement of OPA & 2% PPF Cement obtained as 46.98Mpa, 4.86Mpa and 8.34MPa. 2) The addition of polypropylene fibers could significantly increase the flexural, tensile and compressive concrete strength when the percentages of polypropylene fibers ranged between 0.5 to 3%.The fibers in contact with fibers will produce ductility to the mix which will impart tensile strength to the concrete. From the results it has been concluded that addition of fibers to the concrete will affect positively on compressive, tensile and flexural strengths at different proportions. 3) OPA also serve as strength aider in a cement replacement as a result of the high CaO and SiO2 content. The higher the OPA content, the greater the decelerating effect. Properties of fresh concrete such as Consistency, setting time and workability decreases with increase in OPA admixture replacement. 4) Orange Peel Ash can be used to modify the properties of fresh Concrete as an admixture thus reducing waste disposal on the environment.The use of OPA for concrete work in marine structure or other structures that are exposed to harsh acidic environment should be tried and investigated further. 5) Orange Peel Ash is recommended for used in cement mortar due to the decreased in the final setting time and also used in rendering or plastering.

References

[1] S. M. Metev and V. P. Veiko, Laser Assisted Microtechnology, 2nd ed., R. M. Osgood, Jr., Ed. Berlin, Germany: Springer-Verlag, 1998. Manisha. M. Magdum, Karjinni VV (2016) “Influence of Mineral Admixture (Alccofine 1203) on the Properties of Hybrid Fiber Reinforced Concrete”, American Journal of Engineering Research [2] Mahim Mathur, Ashish Mathur (2018) “Performance of concrete by Partial Replacement of Alccofine 1203”, International Journal of Engineering Research and Technology [3] Divya, S., “Study the Effect of Polypropylene Fiber in Concrete”, International Research Journal of Engineering and Technology, Vol (3), Issue (6), June 2016, pp 616-619. [4] Ramujee, K., “Strength Properties of Polypropylene Fiber Reinforced Concrete”, International Journal of Innovative Research in Science, Engineering and Technology, Vol (2), Issue (8), August 2013, pp 3409 – 3413. [5] Djilas, S., Canadanovic-Brunet, J., and Cetkovic, G. (2009). By-products of fruits processing as a source of photochemical. Chemical Industry and Chemical Engineering Quarterly, 15(4), 191–202 [6] Hassan, K.E., Cabrera, J.G., and Maliehe, R.S. 2000. The Effect of Mineral Admixtures on the Properties of High-Performance Concrete. Cement & Concrete Composites, Vol. 22, pp. 267-271. [7] Partial Replacement of cement with orange peel ash o (Acheampong, A., Adom-Asaomoah, M., Ayarkwa, J., &Afrifa, R. (2013). [8] Comparative study of the physical properties of Palm kernel shells concrete and normal weight concrete in Ghana. Journal of Science and Multidisciplinary Research, 5(1), 129–146.) [9] Djilas, S., Canadanovic-Brunet, J., &Cetkovic, G. (2009). By-products of fruits processing as a source of phytochemicals. Chemical Industry and Chemical Engineering Quarterly, 15(4), 191–202. doi: 10.2298/ciceq0904191d). [10] Milind , V. , “ Performance of Polypropylene Fiber Reinforced Concrete” ,IOSR, Journal of Mechanical and Civil Engineering , Vol(12) , Issue(1) , 2015 , pp 28-36.

Copyright

Copyright © 2024 M. Jahera Bee, P. Subhasri. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET63647

Publish Date : 2024-07-16

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online